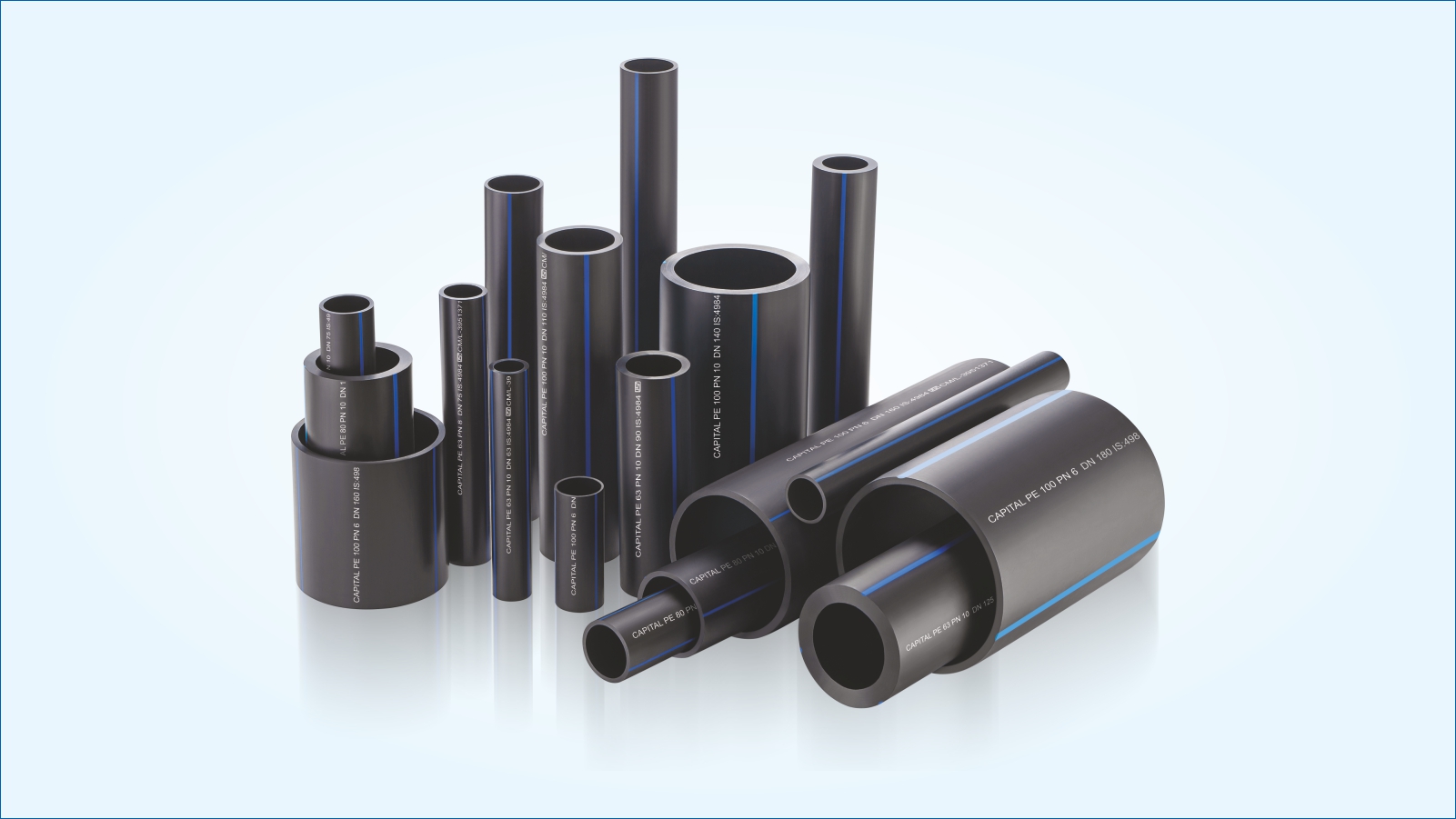

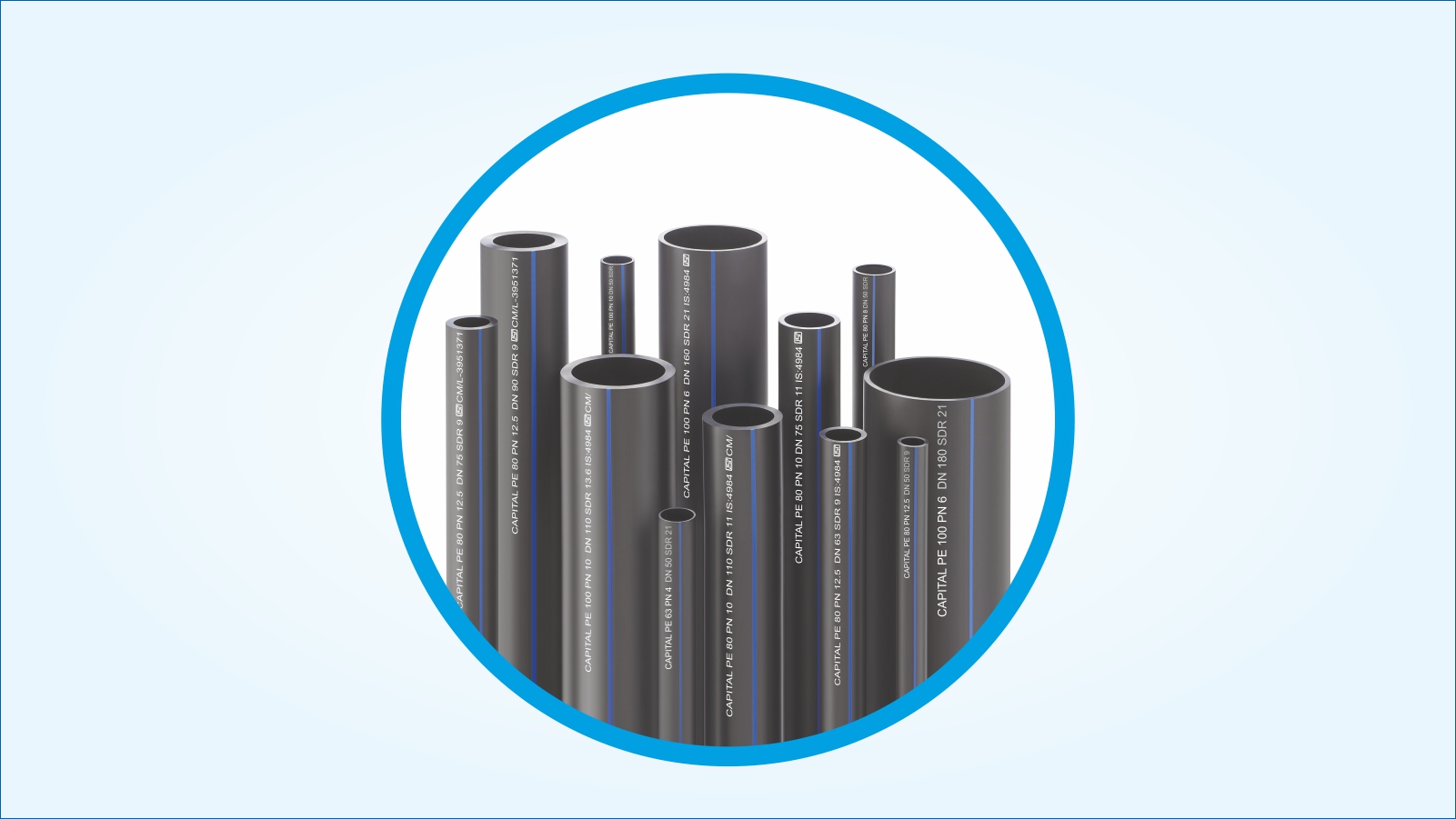

HDPE Pipe

We offer a wide range of High Density Polyethylene (HDPE) Pipes which are uses across various industries as well as water supply in agriculture & domestic purpose. CAPITAL HDPE pipes are manufactured from 100% virgin PE granules to ensure our committment of best quality. HDPE Pipes are the best option in today's market due to its advantages over cast iron G.I. Pipe, mild & stainless steel pipes because of properties like resistence to corrosion, durable, light in weight & flexibility etc.

Specifications

Range Dia. : 16 mm to 450 mm OD

Standard : IS 4984 : 2016

Grade : PE 63, PE 80, PE 100

Color : Blacke with Three Stripes

Application : Water Supply, Lift Irrigation, Drip Main & Distribution Pipe Line, Chemical, Food & Dairy Plants Pipe Lines insted of Metal Or Cement Pipes.

Mechanical and Physical Properties

| Property Value Unit |

| Density (Base Material) 940– 965 Kg/M³ |

| Melt flow index (192°C /2.16 Kg) ≤ 0.3 g /10 Minutes |

| Melt flow index (192°C /5.0 Kg) 0.2 – 1.1 g /10 Minutes |

| VST 120 - 130 °C |

| Crystalline melting Range 130 - 133 °C |

| Viscosity Number 390 Cm³/g |

| Hardness 58 – 65 Shore “ D” |

| Tensile Strength at Yield 20 – 26 MPa |

| Ultimate tensile Strength 30 MPa |

| Elongation At Break >600 % |

| Elastic Modulus 900 - 1200 MPa |

| Flexural Stress (3.5% Deflection) 13.8 – 20.3 MPa |

| Charpy Notched Impact at 0°C 16 KJ/M² |

| Thermal Stability at 210°C ≥20 Minutes |

| Carbon Black Content 2 - 3 % |

PE Pipe Wall Thickness for raised temperature

The wall thickness of pipes are based on the maximum allowable hydrostatic design stress at 30°C water temperature for 50 years of life. In case of variation in water temperature, the working pressure needs to be modified as per given chart. However, occasional rise in temperature as in summer seaoson with concurrent corresponding reduction in temperature during night has no deleterious effects on the life and working pressure of PE pipes

| Generation Material grade Material Method of mfr. | |

|

|

| Remarks: Manufacturing method did not change with the field requirement. | |

|

|

|

|

| Remarks: Method of manufacturing has changed to give better strength to the raw material. | |

|

|

|

Why we choose polyethylene (PE) pipes as against AC/CI or DI?

Polyethylene pipe systems offer significant advantages over ductile iron, steel and cement systems. Some of its advantages are as follows- Longevity: PE pipes have the Long track record of excellent performance, approaching 100 years worldwide.

- Corrosion resistance: PE is basically chemically inert. This pipe system does not rust and corrode. This system resists chemical attack from aggressive soils. There is no need for protective layer or finishing process. PE pipe has very good abrasion resistance also.

- Leak tight: Butt fused joints create a homogenous system. The fusion weld for this system is very strong Therefore, unlike ring type joints or the other mechanical jointing systems, there is no risk of leakage resulting from joint distortion.

- Optimum flow rate: Smooth inside pipe surface allows for a high Hazen-Williams “c” factor. “c” remains constant throughout the lifetime of the system due to an innate high resistance to scale and biological build up.Polyethylene (PE) is also biologically inert.

- Excellent water hammer characteristics to withstand surges: The inherent properties of polyethylene allow the system to significantly lower the effect of surges compared to PVC and ductile iron systems.

- Flexibility: PE pipes can be coiled and supplied in length of up to 300m for small diameter pipes. This feature is one of the ma ny contributions to cost savings during the installation process.

- Resistance to geological conditions: PE piping systems have inherent resistance to ground temperature fluctuations and earth instability because of high impact and breakage resistance.

- Seismic Resistance: The toughness, ductility and flexibility of PE pipe combined with its other special properties, such as its leak-free fully restrained heat fused joints, make it well suited for installation in dynamic soil environments and in areas prone to earthquakes.

- Abrasion Resistance: PE pipe is a frequent choice for the transport of granular or slurry solutions, such as sand, fly ash and coal. The advantage of polyethylene in these applications is its wear resistance, which for example when conveying fine grain slurries has been shown in laboratory tests to be three to five times greater than for steel pipe. PE pipe has elastic properties that under proper flow conditions allow particles to bounce off its surface. This feature combined with PE’s toughness results in a service life that exceeds that of many metal piping materials. There are several factors that affect the wear resistance of a pipeline. The concentration, size and shape of the solid materials, along with the pipe diameter and flow velocity, are the major parameters that will affect the life of the pipeline.

- High strain allowed virtually eliminated failure due to freezing pipes.

- PE pipe can Achieve Maximum Cold Bending Radius

- Reduced installation costs

Jointing Methods

- Butt Fusion

- Saddle Fusion

- Electro Fusion

- Flange Joint

- Insert Joint

- Compression Joint

- Shoulder Groove Joint

- Sure Loc Joint

- Threaded Joint.

Capital Polyplast manufactures PE Pipe and Fittings which are widely accepted in following applications.

| Industrial | Infrastructure | |||||||

| • Untreated and Treated Effluent | ||||||||

| • Chemical Process Lines | • Stay Cable Pipe for Cable Stayed Bridges | |||||||

| • Corrosive Liquids | • Desalination Plant | |||||||

| • Effluent Disposal | • Culverts and Storm Water Drains | |||||||

| • Building & Construction | • Thermal & Nuclear Power Station | |||||||

| • Fertilizers | • Hydel Power Plants | |||||||

| • Food Processing Industry | • Dredging & Sand Stowing | |||||||

| • Marine Intake and Outfall | • Infiltration Gallery | |||||||

| • Salt Pan | ||||||||

| • Fire Fighting Systems | Mining Industry | |||||||

| • Material Handling - Pneumatic Conveyance | • Leach Lines | |||||||

| of Particulates | • Coal Decant Systems | |||||||

| • Fly-Ash Slurry and others | • Mine Drainage | |||||||

| • Coal Tailings | ||||||||

| Sewerage | • Slurry and Sludge Transport | |||||||

| • Pumping Main for Sewerage | • De-watering | |||||||

| • Force Main for Sewer | • Dust Suppression | |||||||

| • Gravity Main for Sewer | • Sand Stowing | |||||||

| • Rehabilitation of Sewer Lines | ||||||||

| Gas & Air | ||||||||

| Irrigation & Agricultural | • Natural and LP Gas Distribution | |||||||

| • Rising Main & Distribution Systems | • Coal Bed Methane Gas Collection | |||||||

| • Lift and Gravity Irrigation | & Distribution | |||||||

| • Drip Irrigation | • Air: Chilled air conveyance | |||||||

| • Gated Pipe Irrigation | • Bio-gas conveyance | |||||||

| • Sprinkler Irrigation | • Inert gas conveyance (argon, | |||||||

| • Sub Soil Drainage | nitrogen, helium) | |||||||

| • Aquaculture | ||||||||

| Ducting | ||||||||

| Municipalities, Corporations and Public Utilities | • Electrical Cable Ducting | |||||||

| • Pumping Mains for Water | • Telecommunication Cable Ducting | |||||||

| • Potable Water Distribution System | • Optical Fibre Cable Ducting | |||||||

| • House Service Connections | • Micro Duct - House Connections | |||||||

| • Waste Water Treatment Plants. | ||||||||

| • Aeration and Odour Control Ducting | ||||||||

| • Landfill - Leachate Collection & | ||||||||

| Conveyance | ||||||||

| • Landfill - Methane Gas Extraction | ||||||||

| & Convenyance | ||||||||

Advantages of HDPE Pipes

- Long Efficient 100 years of Service Life

- Light in Weight, Flexible and Fatigue Resistant

- Joints are Monolithic and 100% Leak-proof

- Operation and Maintenance Cost as good as NIL

- Low Energy Consumption & shall Not Increase with Time (highest C value among pipe MOCs, Hazen Williams C value = 150)

- Acidic or Alkaline soil-state environment do not affect

- Lowest Water Hammer/Surge pressure effect among all pipe materials

- Resistant to Hydrogen Sulphide Gas, High Abrasion Resistance

- Superior Chemical Resistance Fluid pH ranging from 1 to 14

- Suitable in Earthquake Prone area & Unstable Soil Strata

- Suitable for Underwater Installation (construction advantages)

- Suitable for Undulating Land

- Low Life Cycle Cost due to Non-bio Degradability & Low Pumping Cost

- Offers many advantages in Trenchless Construction

|

S.No. |

Features Characteristics |

|

|

1 |

Life Expectancy |

PE Pipe has a Life Expectancy of about 100 years. |

| 2 | Joint |

PE pipe is normally joined by butt fusion method which creates a joint that is as strong or |

| 3 | Leak Proof |

Butt-fused joints create a homogenous, monolithic joint leading to leak proof system. |

| 4 |

Corrosion Resistance |

Does not rust, rot, or corrode. Capital PE pipes are non-conducting and inert and hence immune to |

| 5 | Chemical Resistance |

PE pipe has excellent chemical resistance. pH is 1 to 14 |

| 6 | UV Protection |

Black PE pipe containing 2 to 3.0% carbon black can be safely used outside in the sun without |

| 7 | Impact & Toughness |

Tough and good Impact Resistance. |

| 8 | Pressure Ratings & Dia, |

PE pipe is available in various sizes 16mm 450 mm dia. and pressure ratings of PN-2, PN2.5, PN-3.2, |

| 9 | Lightweight |

It is lighter than Metal or Concrete pipe. |

| 10 | Flexibility |

PE pipe can be bent to a minimum radius of 25 times the pipe diameter. This flexibility of PE pipe |

| 11 | Coiled Pipe |

PE pipe is also available in coil form upto 140mm dia. with specific SDR. |

| 12 |

Earth quake / Soil |

Found good in case of earth quake and soil settlement. Capital PE pipes have excellent resistance to |

| 13 | Water Hammer |

The water hammer effect in the Capital PE pipes are the lowest when compared to conventional pipes |